Flame cutting is recognised as the perfect solution for cutting steel profiles from carbon and low alloy steels within a range of 3mm to 450mm thickness.

Accuracy is generally achieved between +/- 1mm to 10mm depending on thickness of the metal used and due to its high speed, high accuracy, our multi-head CNC flame cutting produces accurate and repeatable steel profile pieces.

This process typically provides an inexpensive cutting of carbon steel and most alloy steels. Flame cutting does create a heat affected zone (HAZ) around the cut that may require removing by an additional machining stage

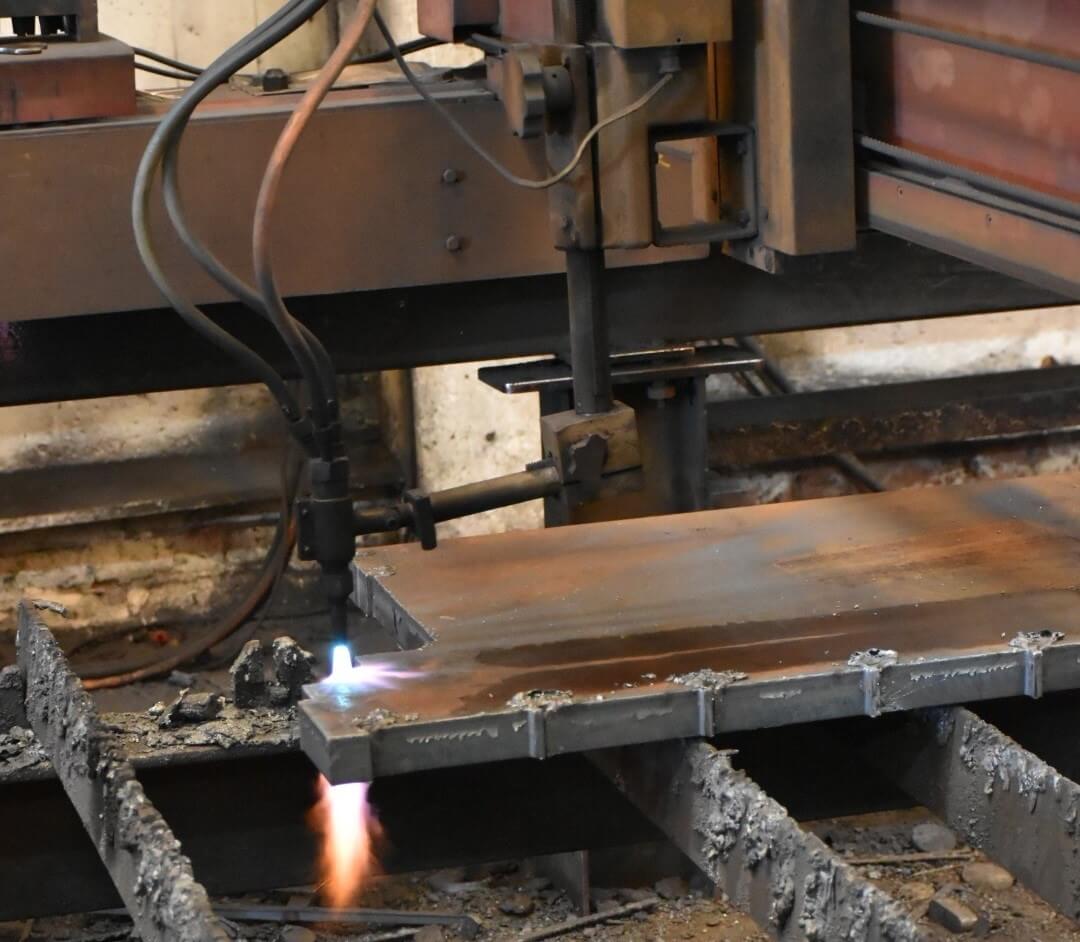

Flame cutting a steel profile uses a combination of gases – typically oxygen and propane – to create a controlled flame that heats the metal to melting point and blasts away the molten, oxidised slag to create a slot right through the metal. Thicknesses of over 450mm can be flame cut.

CNC Flame cutting uses multiple-torches, this means that the process is ideal for high volume production runs of steel profiles that need repeatable accuracy.

Flame cutting is an ideal process to be paired with a secondary machining process such as lumsden grinding which can apply additional machining to Heat Affected Zones (HAZ) and can deliver an improved final product.

Flame cutting is capable of cutting much thicker profiles than laser cutting, whilst a flame cutter can cut profiles up to 450mm or more and laser cutter is limited to around 25-30mm. Laser accuracy is greater that flame cutting, whilst flame cutting is accurate to 1-3mm, laser cutting can be accurate to better than 1/10 mm.